A high-temperature ultrasonic fatigue tester is expected to create significant new opportunities for student and faculty researchers at The University of Toledo College of Engineering.

“We’re grateful to the U.S. Department of Defense, which funded its purchase under the Defense University Research Instrumentation Program,” said Dr. Meysam Haghshenas, an assistant professor in the Department of Mechanical, Industrial and Manufacturing Engineering and director of the Failure, Fracture and Fatigue Laboratory. “This is a very specialized piece of equipment, and we are excited to be the only academic research lab in the country to have onsite access to this model. It’s going to enable us to pursue exciting and cutting-edge research in partnership with a wide variety of organizations including the U.S. Department of Defense.”

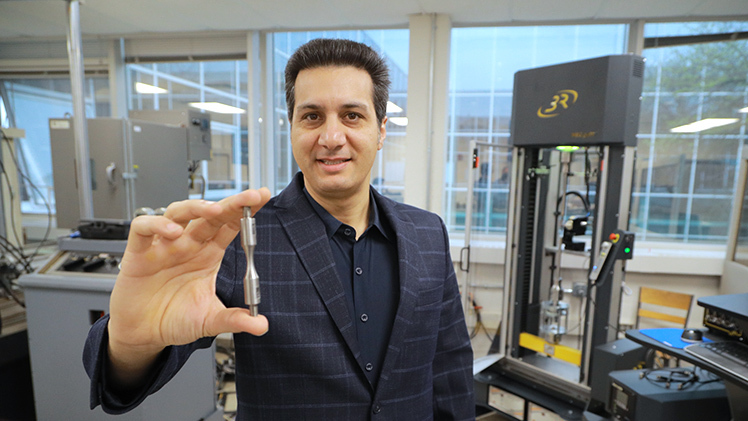

Dr. Meysam Haghshenas, an assistant professor in the Department of Mechanical, Industrial and Manufacturing Engineering, holds an hourglass test specimen in front of the new high-temperature ultrasonic fatigue tester in the the Failure, Fracture and Fatigue Laboratory.

The U.S. Department of Defense awarded a total of $59 million to 147 university researchers for fiscal year 2023 under the highly competitive Defense University Research Instrumentation Program (DURIP). These awards have financed the purchase of research equipment at 77 institutions across 30 states, enabling universities to perform state-of-the-art research.

Haghshenas and UToledo received $237,205 in an equipment grant sponsored by the Air Force Office of Scientific Research. The funds covered the purchase and installation of the high-temperature ultrasonic fatigue tester, which was installed this month in Haghshenas’ Failure, Fracture and Fatigue Laboratory.

“The University of Toledo and Dr. Haghshenas are to be commended for securing this major award from the Air Force Office of Scientific Research to advance science and benefit both student and faculty researchers,” said Congresswoman Marcy Kaptur, who represents Ohio’s Ninth Congressional District and is a senior member of the House Appropriations Subcommittee on Defense. “Nationwide, only 147 researchers were selected as part of the Department of Defense University Research Instrumentation Program. This investment in high-temperature ultrasonic fatigue testing expands the capabilities of UToledo’s Failure, Fracture and Fatigue Laboratory and places it at the forefront of cutting-edge of high science and federal research.”

The new equipment joins five fatigue testers already at the College of Engineering, three of which are in the Failure, Fracture and Fatigue Laboratory. The new high-temperature ultrasonic fatigue tester expands the capabilities of these older machines by allowing researchers to now test materials under elevated temperatures and very high rates of cyclic loading (20,000 cycles).

Fatigue is defined as failure under cyclic loading, which is the application of repeated stresses or strains on a structural component. It’s essentially the data-backed study of wear-and-tear on materials with moving components, like an engine, a propeller or even a bridge bearing the weight of vehicles that travel across it over decades.

It should never be left up to chance or guesswork, Haghshenas said.

“Fatigue is responsible for up to 90% of all mechanical failures,” Haghshenas said. “And those failures can be catastrophic, as we see in examples like plane crashes and bridge collapses that are reported in the news. That’s why it’s so important that we study fatigue.”

Haghshenas is currently a principal investigator or co-principal investigator on four grant-funded research projects related to fatigue through the U.S. Department of Defense. Last semester he and two graduate students began using an ultrasonic fatigue tester to test copper alloys, for various Navy and Marine applications like submarine propellers, under highly corrosive environments intended to mimic the long-term effects of seawater. This work is funded by a three-year grant valued at $436,827 from the Office of Naval Research.

The new equipment will allow researchers to test the materials at temperatures up to 1,200 Celsius and for a fatigue life up to 10 billion cycles, as requested by the updated Air Force Engine Structural Integrity Program. Because it is an ultrasonic fatigue tester it can apply loading cycles at a frequency of 20 kilohertz (kHz), reducing the time required to conduct a test to hours rather than the days, weeks or even months that would be needed with lower-frequency machines.

“There are some other ultrasonic fatigue testers around the U.S., but they all operate at ambient temperatures,” Haghshenas said. “That’s not necessarily helpful when we’re talking about aircraft engines, for example. So the uniqueness of this system is that a high-temperature model has been integrated with an ultrasonic model. We’re excited to see what opportunities it will create for the Failure, Fracture and Fatigue Laboratory and for the College of Engineering.”