When the U.S. Army Corps of Engineers replaced an arrestor arm in one of two active locks recently in Sault-Sainte Marie, Michigan, not a single freighter was re-routed or delayed — no small achievement at this major transit point for domestic iron ore, where the Department of Homeland Security predicted an unanticipated closure would be “catastrophic for the nation” in a study released in 2015.

So how did the corps manage this formidable task?

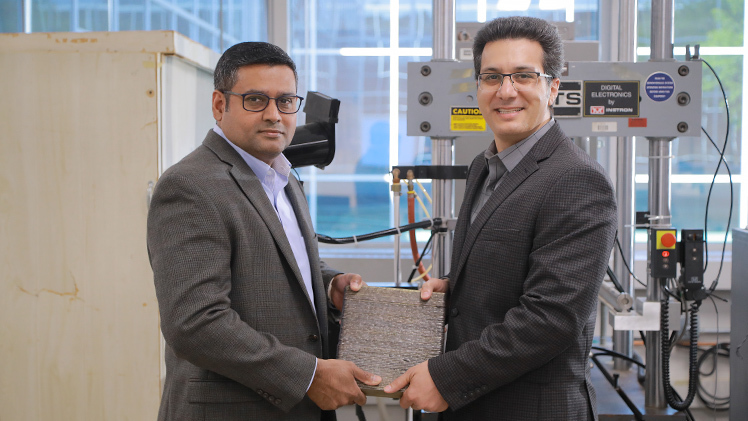

Dr. Joseph Lawrence, associate professor in the Department of Chemical Engineering, and Dr. Meysam Haghshenas, assistant professor in the Department of Mechanical, Industrial and Manufacturing Engineering, show off a sample of the material used to replace an arrestor arm at the Poe Lock inside Haghshenas’ Failure, Fracture and Fatigue Laboratory.

The 12-foot metal arrestor arm is the largest civil works infrastructure component ever produced by 3D printing in the United States, and it was made possible in part by research completed at The University of Toledo.

“UToledo’s collaboration with Eaton Corporation and the U.S. Army Engineer Research and Development Center on a research project focused on civil works infrastructure played a key role in evaluating the material used for large-format wire arc additive manufacturing to replace a mechanical component on the Poe Lock,” said Dr. Joseph Lawrence, principal investigator and an associate professor in the Department of Chemical Engineering at UToledo. “It’s exciting to now see the real-world applications of the work we’ve done in the lab.”

As mechanical components of aging civil works like locks, dams and hydropower facilities wear out, site managers are increasingly interested in additive manufacturing, known more widely as 3D printing, as an alternative to traditional repair methods. The diversity and complexity of the aging mechanical and structural systems, many of which were originally constructed with vintage manufacturing methods and materials, presents a particular challenge. Additive manufacturing is attractive for its potential to produce faster, cheaper and in some cases better replacement parts.

The Poe Lock arrestor arm is a clear example: It was manufactured in 12 weeks, compared to a projected 18-month lead time for conventional manufacturing, then installed, tested and commissioned during the Soo Locks’ winter ten-week maintenance cycle.

The U.S. Department of Defense, via the U.S. Army Engineer Research and Development Center, has funded research into this application of additive manufacturing by UToledo and Eaton Corporation since January 2022. Eaton Corporation is the power management company with an Additive Manufacturing Center of Excellence in Southfield, Michigan.

UToledo’s contributions have leveraged its Polymer Institute and Center for Materials and Sensor Characterization, directed by Lawrence, and its Failure, Fracture and Fatigue Laboratory and Micro/Nano-Mechanics Laboratory, directed by Dr. Meysam Haghshenas, a co-principal investigator and assistant professor in the Department of Mechanical, Industrial and Manufacturing Engineering.

“This collaboration between UToledo, Eaton, and the U.S. Army Corps of Engineers demonstrates the efficiencies that can be achieved when federal agencies, academia and private industry use 21st century technology to modernize 20th century infrastructure,” said U.S. Representative Marcy Kaptur, who represents Ohio’s Ninth Congressional District. “Through collaboration, the Soo Locks will continue to facilitate international and interlake commerce for the Great Lakes region.”

Lawrence’ and Haghshenas’ research has specifically been focused on the use additive manufacturing of polymer and composite materials for temporary repairs and of metal for permanent replacement of unique parts, as well as in-situ repair technologies.

Toward the Poe Lock arrestor arm, UToledo also headed the fatigue evaluation of steel parts created through additive manufacturing. Fatigue concerns wear-and-tear on materials that experience repeated stresses or strains.

“Fatigue failure is a critical integrity issue when it comes to civil works like the Poe Lock,” Haghshenas said. “We were excited to lend our expertise to this project, and we look forward to continuing to collaborate with Eaton Corporation and the U.S. Army Engineer Research and Development Center.”

Any opinions, findings and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the U.S. Army Engineer Research and Development Center.