University of Toledo faculty and students are spending their summer running experiments and calculations that will directly support industry innovations.

Working alongside Hyliion, a developer of sustainable electricity-generating technology, they’re bringing expertise in power conditioning circuitry to facilitate the integration of an advanced electric generator system, Hyliion’s KARNOTM Core, for the U.S. Navy.

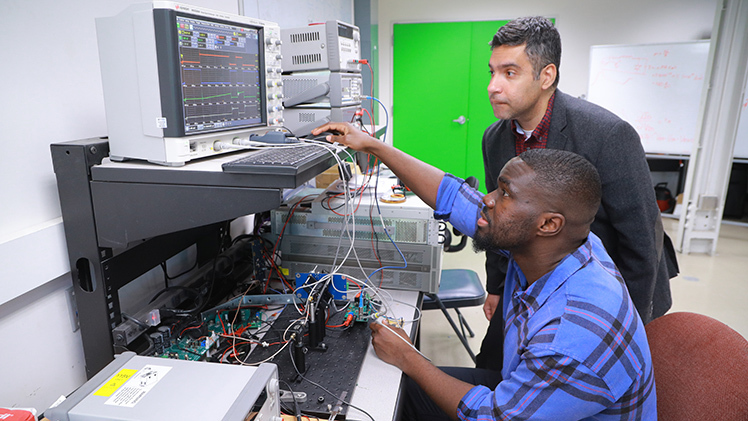

Samuel Atwimah, a Ph.D. student in electrical engineering, and Dr. Raghav Khanna, the Leidich Family Endowed Professor of Power Systems in the College of Engineering.

“We’re exploring how to make the electric power that the generator produces compatible with various systems and components in a vessel,” said Dr. Raghav Khanna, the Leidich Family Endowed Professor of Power Systems in the College of Engineering. “This work is resolving critical questions about how to integrate the onboard power generation effectively with the navigation and communication systems, for example.”

Khanna is leading a team of five faculty — two fellow engineers in the Department of Electrical Engineering and Computer Science as well as a physicist and mathematician representing the College of Natural Science and Mathematics — and seven undergraduate and graduate students in the research that directly supports Hyliion’s work with the U.S. Navy.

The KARNO Core is a groundbreaking fuel-agnostic solution that utilizes a linear generator architecture to produce electricity both economically and efficiently. It uses a sealed system in which thermal energy causes a working gas to expand and drive pistons through a magnetic field, generating electric current. The system is designed to operate with more than 20 different fuel types, including hydrogen, ammonia, LPG and natural gas.

Some of the crucial internal components of the KARNO Core are produced through additive manufacturing, allowing for intricate geometries that improve thermal performance and system compactness. The generator is designed for high efficiency, low noise and minimal maintenance requirements, characteristics that make it suitable for environments where fuel flexibility, durability and consistent performance are critical — such as marine and remote applications.

Last year the Office of Naval Research awarded Hyliion $15 million-plus to develop the KARNO CORE for use in U.S. Navy ships and stationary power applications.

“Collaborating with UToledo brings deep technical insight and academic rigor to our work developing the KARNO Core for naval applications,” said Thomas Healy, founder and CEO of Hyliion, which is based in Austin, Texas, with offices in Cincinnati. “Their expertise in power systems and dynamic modeling is helping us refine performance and strengthen resilience in real-world maritime conditions. We’re excited to work with such a talented team to advance energy innovation for the U.S. Navy.”

Hyliion is working closely with UToledo, where researchers are taking the lead this summer on a question related to the metronome effect. The metronome effect is a phenomenon in physics in which multiple oscillators, like metronomes or in this case pistons, self-synchronize under some conditions.

“The Navy has tasked us with exploring if the ocean’s waves would trigger the metronome effect, which could create a force that could impair the operation of the vessel,” Khanna said. “If it’s found they do, we also want to develop mitigation strategies to prevent the metronome effect from occurring. This will keep the naval system robust and reliable. We will then look to explore methods of utilizing electricity produced from the KARNO Core for various components on the ship.”

Khanna is enthusiastic about the six-month project and the opportunity for continued collaboration with Hyliion.

“It’s exciting to see our research directly support innovation in the industry,” he said. “We also hope to have a continued relationship with Hyliion.”