Three-dimensional printing is opening doors across industries, allowing scientists to develop new alloys and composites that are stronger, lighter and better suited than their predecessors to applications ranging from aircraft engines to high-speed trains.

Before these new materials make their way to manufacturing facilities, though, they need to be thoroughly tested: How much wear and tear can they take?

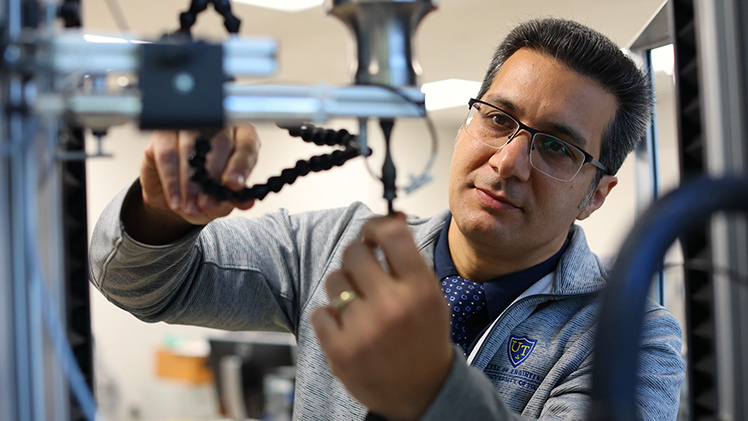

Dr. Meysam Haghshenas heads the College of Engineering’s Failure, Fracture and Fatigue Laboratory, where he uses high-tech equipment to study how materials weaken under repeated stresses or strains.

The University of Toledo is uniquely positioned to answer these questions thanks to a high-temperature ultrasonic fatigue tester funded through the U.S. Department of Defense’s Defense University Research Instrumentation Program.

Dr. Meysam Haghshenas, an associate professor in the Department of Mechanical, Industrial and Manufacturing Engineering, recently received research awards from two federal agencies to use this cutting-edge equipment to compile data on promising materials. He will soon begin studying a nanocomposite for the National Science Foundation (NSF) and two alloys for the National Aeronautics and Space Administration (NASA).

“These awards reflect our unique capability to test both in the conventional (low- and high-cycle) fatigue domain and the very high cycle fatigue regime,” Haghshenas said. “It is a perfect example of how strategic investment in cutting-edge instrumentation can bridge agencies and catalyze fundamental scientific discovery at the core of national interest.”

Haghshenas heads the College of Engineering’s Failure, Fracture and Fatigue Laboratory (F3L), where he studies how materials weaken under repeated stresses or strains. Engineers study fatigue as a means of preventing mechanical failure, which can result in catastrophes as dramatic as plane crashes or bridge collapses.

Haghshenas and his collaborators rely on several fatigue testers to speed up the usual wear-and-tear process, but it is a high-temperature ultrasonic fatigue tester installed last year that distinguishes his laboratory nationally. Capable of testing materials at extremely high temperatures and extremely high levels of cyclic loading, the fatigue tester has opened numerous opportunities to the researcher and his undergraduate and graduate student collaborators, including the latest from the NSF and NASA.

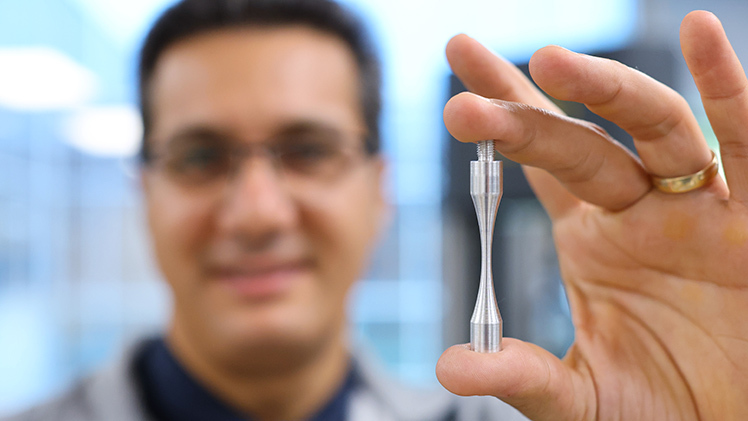

Dr. Meysam Haghshenas holds an hourglass test specimen for use in a fatigue tester inside his Failure, Fracture and Fatigue Laboratory.

Under the two-year, $149,999 NSF award, Haghshenas and a graduate student will investigate the extended fatigue life of a newly developed aluminum-copper nanocomposite, first at ambient and then at the high temperatures to which aerospace equipment might reasonably be exposed.

“We already know that aluminum-copper alloys are very attractive for aerospace applications. They’re lightweight, they’re high strength and they have very good performance,” Haghshenas said. “The material we’re testing stands out because it is additively manufactured and because it’s a nanocomposite, which means that it’s been reinforced with ceramic nanoparticles that make it even stronger.”

The award also encompasses an educational component. Haghshenas plans to welcome high school students in the Toledo Excel scholarship incentive program to his laboratory to learn about the basics of fatigue.

Under the one-year, $87,010 NASA award, Haghshenas and a graduate student will investigate the full spectrum of the fatigue life of two copper-chromium-niobium alloys of interest for future missions to the moon and Mars.

Their findings for each project will be shared widely to advance manufacturing technology.

“The U.S. Department of Defense provided the critical infrastructure that’s empowering these fundamental investigations,” Haghshenas said. “I’m very excited to be able to make this connection between the DOD, the NSF and NASA.”