Two-dimensional, or 2D, layered materials are expected to be next-generation building blocks for electronics and batteries, as well as aerospace, automotive and health-care equipment.

The National Science Foundation awarded an engineer at The University of Toledo a three-year, nearly $400,000 grant to refine his newly developed method to continuously and rapidly produce 2D-layered materials using high-pressure gases, into a means for mass production with the potential to transform U.S. manufacturing.

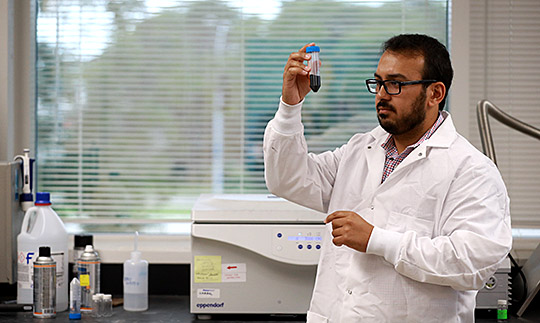

Dr. Reza Rizvi, assistant professor of mechanical, industrial and manufacturing engineering, looked at a dispersion of graphene that was produced using his rapid and scalable exfoliation process. This new process can enable low-cost, flexible and printable electronic devices.

Dr. Reza Rizvi, assistant professor in the Department of Mechanical, Industrial and Manufacturing Engineering and the project’s principal investigator, said the main challenge is the high cost of production.

“Our process called compressible flow exfoliation is capable of continuously producing quality 2D-layered nanomaterials using a supersonic flow of high-pressure gases in just a fraction of a second. Comparable processes take minutes, hours or even days,” Rizvi said. “Using this grant, we will investigate the fundamental mechanisms and process issues, and we will devise strategies for scaling the process to industrial production so that we can take this process out of the lab and into the factory.”

According to the NSF grant, “The results of this work advances the nation’s prosperity and security by boosting competitiveness of U.S. manufacturing efforts on the international stage and promoting broader adoption of two-dimensional materials into next-generation nanotechnology-enabled products.”

Rizvi’s research was recently published in the scientific journal Advanced Materials.