Superman is known to be faster than a speeding bullet, more powerful than a locomotive, and able to leap tall buildings in a single bound.

That’s nice and all, but what can “the Man of Steel” do about drop-foot syndrome, a spine in need of stabilization, or moving an esophagus out of harm’s way during medical procedures?

That’s where Dr. Mohammad Elahinia, assistant professor of mechanical, industrial and manufacturing engineering, comes in.

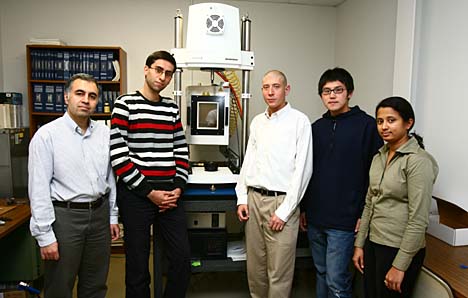

Posing by a high-frequency temperature-controlled test instrument that is used to characterize thermomechanical and fatigue behavior of nitinol devices are, from left, Dr. Mohammad Elahinia; Majid Tabesh and Walter Anderson, master’s students in mechanical engineering; Shuo Wang, an electrical engineering doctoral student; and Minal Bhadane, a biomedical engineering doctoral student.

Elahinia is “the Man of Nitinol.” He’s been working with nitinol, an alloy made of nickel and titanium, since his grad school days at Virginia Tech and during his five years in UT’s Dynamic and Smart Systems Laboratory.

Due to nitinol’s ability to accommodate large strains and its physiological and chemical compatibility with the human body, the alloy is one of the most used materials in medical devices.

“Nitinol alloys have two advantages,” Elahinia said. “It’s super elastic, which means it can be deformed significantly more than steel and it still remains functional. It also has shape memory, which means it can ‘remember’ and return to its original shape by exposing it to heat.”

Elahinia is the principal investigator from UT on a new three-year, $3 million grant through Ohio’s Third Frontier Program to create a nitinol commercialization accelerator to help develop the next-generation of biomedical devices. Drs. Sarit Bhaduri, professor of mechanical, industrial and manufacturing engineering and surgery, and Vijay Goel, endowed chair and McMaster-Gardner Professor of Orthopedic Bioengineering, are co-investigators.

Institutions partnering on the grant are Case Western Reserve University, the Cleveland Clinic, NASA Glen Research Center and Norman Noble Inc., a Cleveland-based maker of nitinol devices.

Elahinia believes UT received the Third Frontier grant because its current research with nitinol shows great potential for commercialization.

For example, Elahinia and Drs. Chuck Armstrong, professor and chair of kinesiology, and Samir Hefzy, professor of mechanical, industrial and manufacturing engineering, received a National Science Foundation grant to develop an active ankle-foot orthosis device to help people with drop-foot condition. The device will be put on the leg to enhance function.

“Because of nitinol’s flexibility and memory properties, it can compensate for the loss of muscle force in drop-foot patients,” Elahinia said. “We plan to use our new nitinol commercialization accelerator facility to make a prototype of the device.”

UT also has a patent pending and is actively seeking a licensee for a nitinol screw designed for affixing rods and plates to the spine to stabilize it or correct deformations. The screw was designed in collaboration with Dr. Ashok Biyani, associate professor of orthopedics and chief of the Division of Spine Surgery at University of Toledo Medical Center.

The screw is expected to be especially useful with patients who have osteoporosis.

“Regular screws can loosen as bones deteriorate due to osteoporosis; however, the nitinol screw reacts to body heat when inserted to engage the screw further in the bone as it degrades, to ensure it remains anchored,” Elahinia explained.

Also awaiting a patent is a nitinol-based esophagus positioner, designed to protect patients during an ablation procedure, which is used to treat an abnormal heart rhythm called atrial fibrillation.

During ablation, low voltage electricity is delivered at high frequencies to the two upper chambers of the heart in an attempt to correct its rhythm. However, due to the esophagus’ proximity to the heart, it is susceptible to being burned during the procedure.

Weekly meetings with Drs. Carlos Baptista, associate professor of neurosciences, Haitham Elsamaloty, associate professor of radiology, and Khalil Kanjwal, a cardiology research fellow, helped Elahinia’s group to design the new device that moves the esophagus out of harm’s way during ablation.

The hope is that the nitinol commercialization accelerator will result in even more interdisciplinary projects.

“The nitinol commercialization accelerator will provide technical help in analysis and fabrication of nitinol devices. If faculty members have any ideas they’d like to explore or need to fabricate devices out of nickel titanium, we are here to help,” Elahinia said.

Just like “the Man of Steel.”